Damage in Rails and Crossings: Simulation, Description, Prediction, Optimization

Behavior of Railway Crossings

Behavior of Railway Crossings

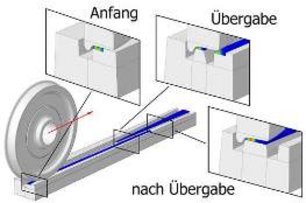

Turnouts are a critical part of the railway track system. They consist of a switch and a crossing panel. It is of crucial interest for the development of new and optimized turnouts to know the distinct loading of the components. A main part of a turnout represents the crossing nose where in facing direction a vertical impact of the wheel occur on the crossing nose or, in the opposite direction coming from the crossing nose on the wing rail. These areas are highly dynamically loaded and at the same time a slip between the wheel and the crossing parts occurs. This is the reason why crossing parts sometimes feature high wear and high damage. Crossings thus have a big influence on the maintenance costs of the tracks. For the necessary service time or the replacement of crossings in the track, there are only small time intervals available. This is another reason for the importance of increasing the service/reparation time and the lifetime of the crossing parts.

Fundamental Research on Damage in the Wheel Rail Contact

Fundamental Research on Damage in the Wheel Rail Contact

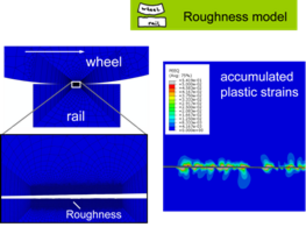

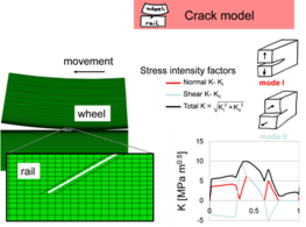

Metallurgical investigations of rolling sliding contact report the very common fact that a layer, very close to the surface of the contacting bodies, is heavily deformed. For the investigation of the plastic straining processes very close to the surface (within 100 microns depth) one needs to consider the surface roughness on a micrometer length scale but also the unevenness of the wheel and rail on a millimeter length scale. Numerical micro-models indicate a crack initiation at asperities. It will be investigated if these cracks must be either related to wear or cracks growing into the depth and their relation to head checks. The main aim is the prediction of growth rate and path of shear cracks which remains an open task in material research. Shear cracks are one of the most important damage mechanisms regarding rolling contact fatigue of rails and crossings. Another aim will be the detection of mechanisms of crack initiation in rolling sliding contacts given arbitrary external thermo-mechanical loading conditions. The aim of a new physically justified wear law is based on preceding numerical and metallurgical investigations.